Prized for their performance and affordability, single-use plastics are at the heart of the modern health science economy and a necessary tool for life-enhancing innovations. While single-use plastics have accelerated the rate of scientific discovery, they have also increased the industry’s dependence on fossil fuels. This year, in the midst of a global pandemic, the U.S. will dispose of greater than 3 billion lbs. of single-use plastics by way of incineration or landfill. This linear process - whereby laboratory products are made, used, and then discarded - necessitates the continued extraction and emission of carbon in the forms of oil and natural gas.

While the single-use plastic problem may seem like a catch-22, where innovation is pitted against the environment, this narrative could not be further from the truth. At the present time, the health science community finds itself straddling the wasteful, unquestioned habits of the past and a future wherein every metric ton of carbon counts. To cross this threshold, we must fundamentally reinvent the single-use plastic life cycle.

Having worked in various laboratories over the years and then as physician-scientists in training at the University of Pittsburgh’s School of Medicine, the environmental consequences of laboratory plasticware became both too obvious and too dire for James and I to ignore. Last year, shortly after participating in the Randall Family Big Idea Competition, we put our medical training on hold to launch Polycarbin.

In order to move beyond the ‘take-make-waste’ model surrounding lab plastic, it was clear that we had to address a design flaw inherent to the products themselves and the infrastructure of regulated medical waste management. While composed of valuable and uniquely recyclable material, the average laboratory product spends the majority of its life buried in a landfill or as carcinogenic ash in our atmosphere. Before reaching this final destination, however, all of these products are decontaminated, rendering them eligible for recycling. James and I realized that if you created a disposal system for lab plastic waste, similar to the segregation already employed for other waste streams leaving this regulated work environment, you could redirect a valuable material stream back into manufacturing supply chains.

The key to our innovation, however, was not only a “fancy” recycling bin. Rather, it was digitizing a supply chain so we could securely track material through its chain of custody thereby ensuring safe and sustainable disposal practices. To accomplish this, Polycarbin leverages a blockchain-enabled resource management platform to track waste stream data, regulatory compliance, and the carbon emissions of the entire supply chain. By introducing an intuitive diversion solution into the laboratory workspace and managing this system with our waste analytics software, plastics that were once lost to a mixed waste stream can be reintroduced in the form of recycled laboratory products. Polycarbin’s solution has the potential to bend the wasteful end of today’s linear supply chain back into the hands of the conscientious consumer.

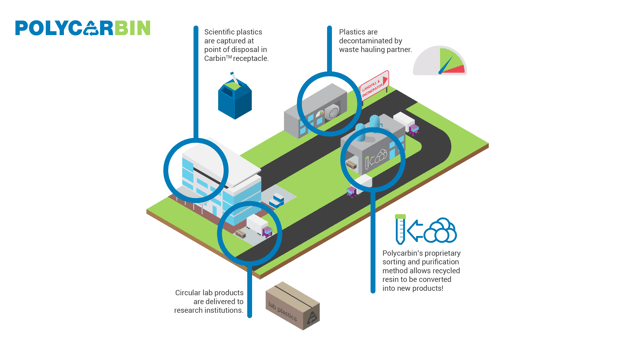

Now, how might this work at the ground level? Well, it begins with our plastic diversion bin, affectionately referred to as the Carbin™. The scientist simply separates their rigid plastic into one of two streams, clear or colored. Once full, the scientist seals the internal waste bags and secures the lid of the Carbin™ that sports a unique QR code. Using the Polycarbin mobile app, the scientist scans the bin, thereby registering the container in our distributed database and notifying partnering waste haulers that another container is ready for pick up. In this way, we are able to monitor the plastic material stream in real-time as it moves through recycling and remanufacturing processes.

Creating a digital footprint for waste drives value for our customers who recognize that sustainable practices create organizational resiliency. With this in mind, Polycarbin’s solution not only creates a more transparent and efficient supply chain, but also quantifies the customer’s carbon offset achieved through recycling. James and I built this company with scientists in mind. As such, we have designed our entire waste analytics software to present personalized carbon emission reduction data to its users giving scientists the first real opportunity to quantify their environmental impact. Finally, so as to complete this virtuous cycle, Polycarbin has partnered with product manufacturers to bring cost-competitive, green products, designed explicitly for recyclability, back to the scientific community.

When confronted with both the enormity of society’s single-use plastics problem and the consequences of a long-ignored climate crisis, a recycling bin and supply chain software may seem wholly inadequate at first. But Polycarbin believes that empowering scientists with the first meaningful opportunity for a sustainable alternative will set a historical precedent and bring new meaning to the life-science ecosystem. With Polycarbin’s solution, a circular economy within the life sciences is not only well within reach, it is already underway.

Connect with Noah Pyles on LinkedIn Connect with James O'Brien on LinkedIn