Hi there, innovators! My name is Joe Slomowitz, but you can call me “Slomo”. I am the creator of slomo’s, a "Platform to Explore 3D Printing Together"!

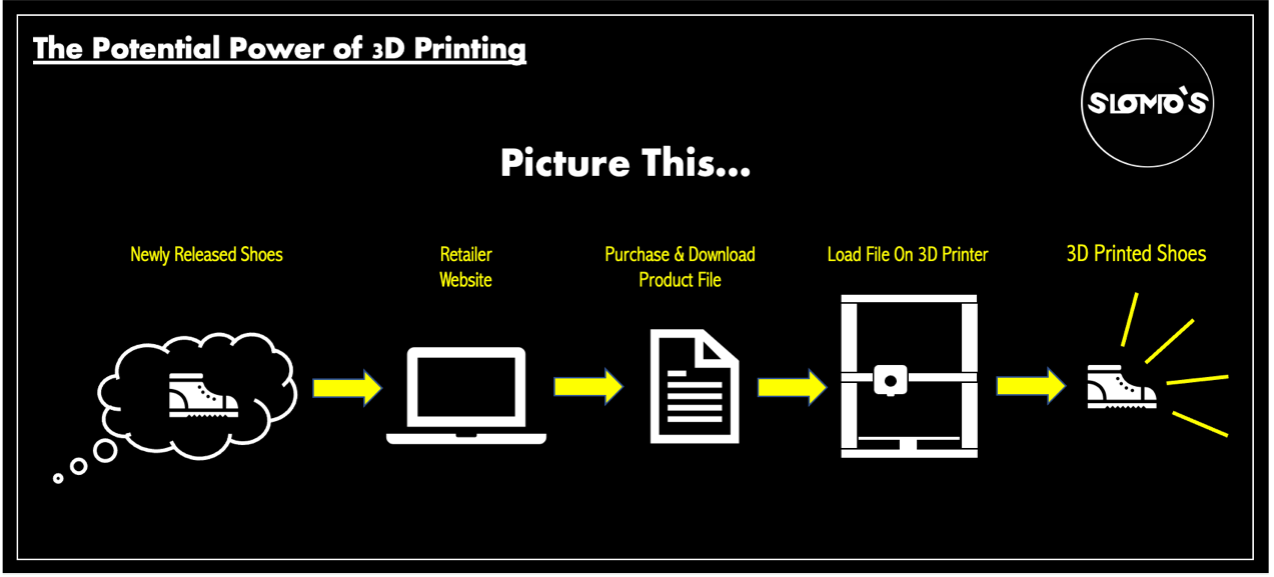

Picture this…

In the future, you want the newest pair of Nike sneakers. Instead of going to a local retail store to buy them, you go online to Nike’s website, buy a file for the sneakers and then load the file into your 3D printer. Within minutes, your new Nike sneakers are made within the comfort of your home and are ready to be worn!

The example above highlights just one of the potential ways that 3D printers could revolutionize the way in which goods are produced, sold and consumed in the future. But before we go any further…. what in the world is 3D printing??

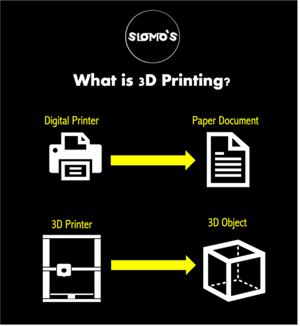

What is 3D Printing?

At the most basic level, 3D printing is similar to digital printing, which you most likely use on a daily basis to print word documents and images. But, instead of printing two-dimensional text or images on a piece of paper, you use a special printer to print physical, three-dimensional objects. And instead of using ink cartridges, you use a more special, heavy-duty ink.

Still not sure what 3D printing is? Watch my video “What is 3D Printing?”.

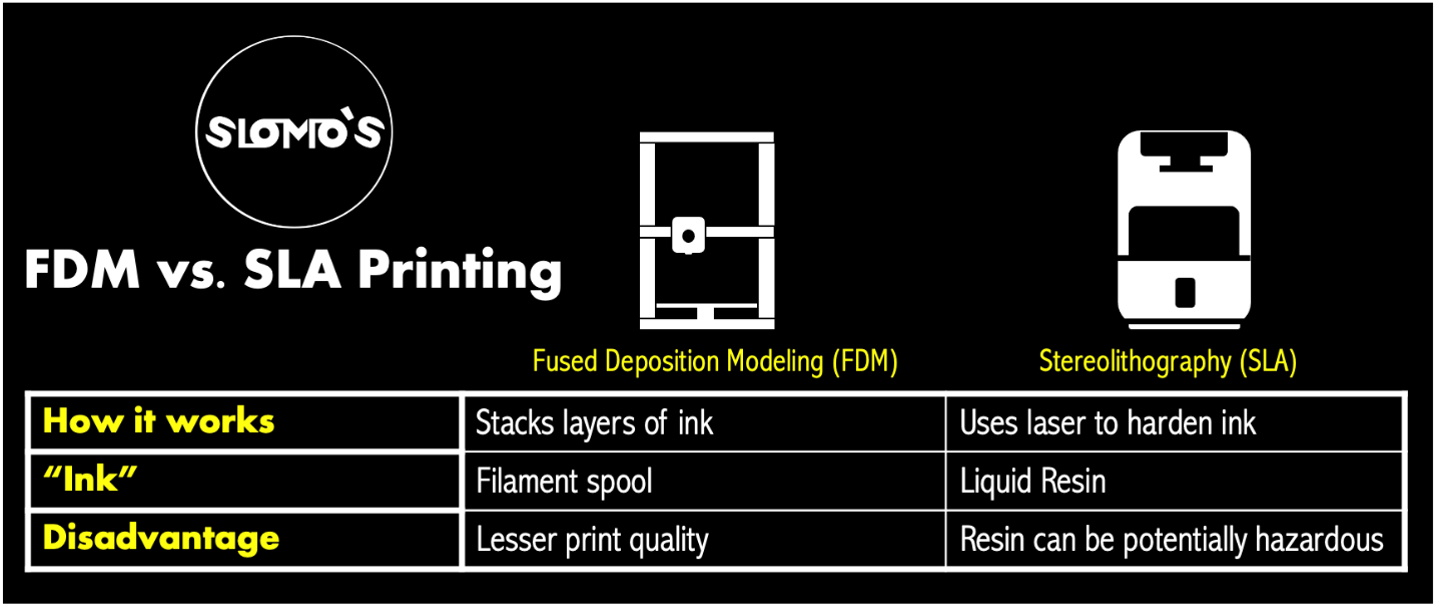

There are several different types of 3D printing, but two of the most common types are 1) “Fused Deposition Modeling (FDM)” and 2) “Stereolithography (SLA)”:

- Fused Deposition Modeling (FDM): This type of 3D printing is most similar to digital printing as it utilizes an ink distributor that runs back in forth, dispensing ink in particular ways to form shapes much like a digital printer. But in order to create three-dimensional objects, an FDM 3D printer stacks layers of its special ink on top of one another. The ink that FDM printers use is called “filament” and comes in spools.

- Stereolithography (SLA): A type of 3D printing in which a laser is shot into a container of liquid resin (the ink) and hardens the resin to form three-dimensional shapes.

The figure below compares the two types of 3D printing:

Fused Deposition Modeling or FDM printing is the most popular type of 3D printing and is the type of 3D printing that I use. I will be referring to FDM printing for the remainder of this article.

What is 3D Printing Used For?

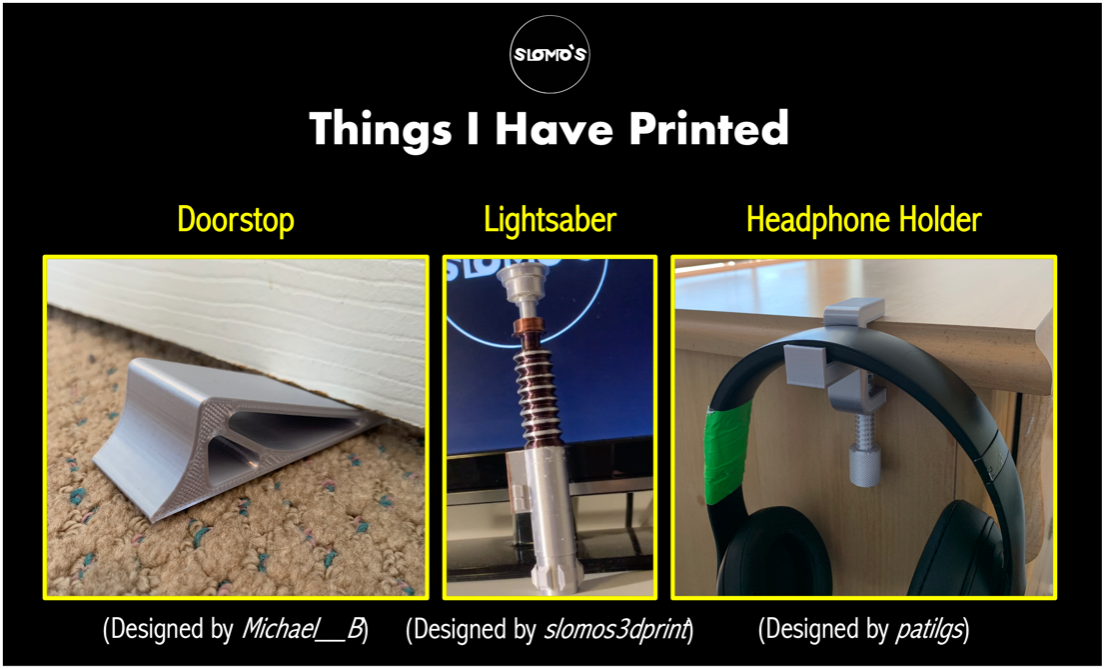

Today, 3D printing is used for both personal and business purposes. At a personal level, individuals often use their 3D printers to make knickknacks like fidget spinners and movie-props, or even helpful tools to use around their homes. For example, I recently needed a doorstop and used my 3D printer to print one (see the doorstop in the picture below)!

It is important to note that 3D printer owners do not need to know how to create 3D models using a computer modeling program in order to 3D print. While knowing how to create 3D models can allow you to create custom prints, there are websites online such as Thingiverse that provide 3D printer owners access to thousands of 3D models created by other 3D printer owners which are easy to download and print! In fact, the doorstop that I printed was a community created 3D model which I downloaded through Thingiverse.

The picture below shows some of the many cool things I have printed with my 3D printer:

At the business level, companies have begun to incorporate 3D printing into their manufacturing processes by using 3D printers to either create specific parts of their products or specialized tools that are needed in order to create their products. Boeing and Heineken are two fantastic examples of companies utilizing 3D printing for these purposes. Boeing has utilized 3D printing to create full pieces of their CH-47 Chinook helicopters, while Heineken recently began using 3D printing to create specific replacement parts for their manufacturing equipment.

The picture below shows a neon-green 3D printed replacement part, implemented onto a piece of manufacturing equipment at one of Heineken’s production facilities:

Source: Van de Staak, Steven. “Heineken: Ensuring Production Continuity with 3D Printing.” Ultimaker.com, Ultimaker BV, 20 May 2019, https://ultimaker.com/learn/heineken-ensuring-production-continuity-with-3d-printing

At both the personal and business level, the key value that 3D printers provide is allowing their users the ability to produce specialized goods or things at the time they are needed, at a potentially reduced cost and at the location in which they are needed.

Never before have we been this close to achieving nearly instant production of products. And never before have we had access to this level of customization and specialization in terms of production. 3D printing is slowly growing out of its early stages and offers such a wide range of opportunities for the future. I am extremely grateful for having gotten involved with 3D printing so that I can grow alongside it.

Getting Involved with 3D Printing

I was fortunate enough to have my first experience with 3D printing through a computer drafting course during my sophomore year of high school. During the course, I was assigned to a project in which I needed to design, print, and test a fidget spinner. Through this project, I was awestruck by the process of being able to take an idea in my head, design it through a computer modeling program, and then bring it to life inside of the classroom using a 3D printer. As a result of this project, I knew then that 3D printing was something I wanted to learn more about. However, the cost of 3D printing and my extracurricular commitments at the time prevented me from further exploring this fascinating and futuristic art.

Fast forward to the middle of the COVID-19 pandemic, the pandemic situation provided me with the perfect opportunity to reconnect to and further explore 3D printing. In addition, my experience with entrepreneurial activities during my freshman year of college through the Big Idea Center motivated me to search for opportunities to create my own personal brand or small business. From the combination of these two factors, I decided to invest in a 3D printer and create the slomo’s platform!

The process of choosing, ordering, and setting-up my 3D printer was relatively straightforward. I documented this process in my video “Getting Started”.

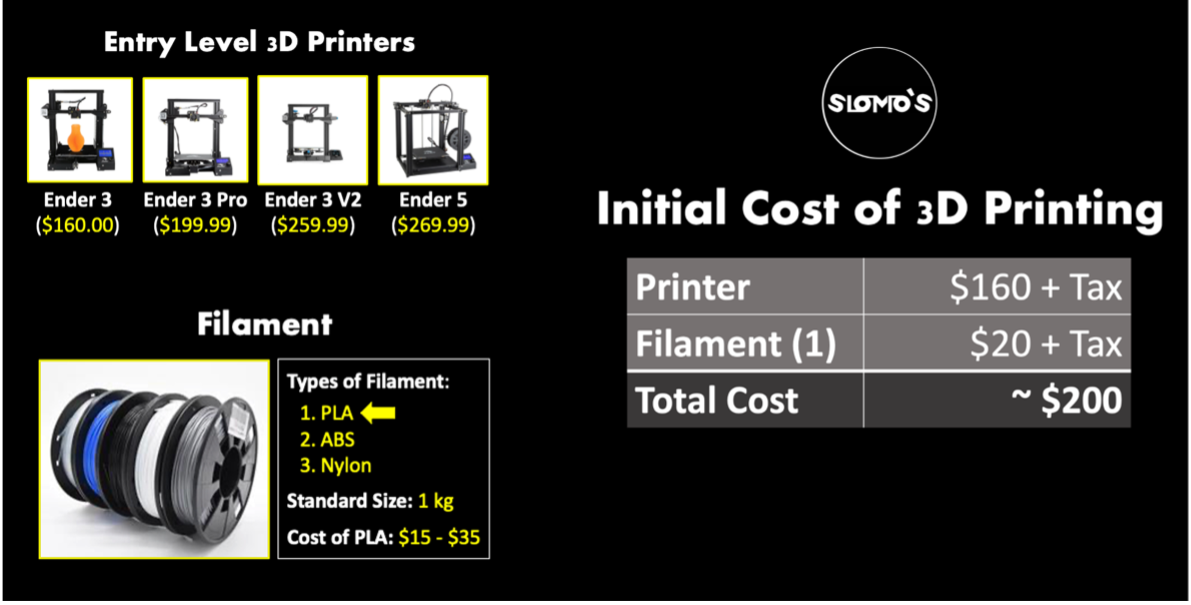

Furthermore, 3D printers have become more accessible and affordable than ever before! Top 3D printer manufacturers such as Ultimaker, Makerbot, and Creality offer large lineups of affordable printers. The price of entry and intermediate level FDM printers range from $150 to $300. And filament can easily be found on Amazon within the price range of $15 to $35.

I purchased the popular and highly recommended Creality Ender 3 printer for $160 (plus tax) and filament for $20 (plus tax). Collectively, I was able to begin 3D printing at just a little over $200, which is remarkably affordable with regards to the value that a 3D printer can offer.

What 3D Printing Means to Entrepreneurs

For entrepreneurs in particular, the value of 3D printing offers an extensive number of business opportunities. Four key opportunities that I believe 3D printers currently offer to entrepreneurs or startups are:

- Production & Sales: Entrepreneurs or startups can use 3D printing to print parts or supplies that go directly into the revenue-generating areas of their businesses. Startups can use 3D printers to print specific parts or the entirety of their products. Startups can also use 3D printers to print merchandise or handouts such as keychains for sales and promotional purposes.

- Operations & Maintenance: Entrepreneurs or startups can use 3D printing to print equipment that fulfills or improves daily operational tasks. For example, startups can use 3D printers to print office equipment such as desk organizers, cable clips and laptop stands or use 3D printers to print replacement parts for broken or missing pieces of equipment such as a broken handle on a tool or a missing lid on a container.

- Prototyping: Entrepreneurs or startups can use 3D printing for research and development purposes to prototype or create mockups of product ideas or inventions. By using their own 3D printers for prototyping, entrepreneurs and startups could potentially avoid the significantly high costs that are often associated with prototyping services.

- Innovating Within 3D Printing: Entrepreneurs or startups may focus on addressing and innovating on business opportunities directly within the growing 3D printing industry.

Furthermore, I would like to highlight two key areas for business opportunities and innovation within the 3D printing industry.

Areas for Innovation Within 3D Printing

In terms of innovations related to 3D printing, two major areas within 3D printing that I believe have large potential for growth within the next couple of years include:

- 3D printing with different materials: Currently, plastics are the most common and accessible 3D printing materials. While many companies have started to use 3D printers that can print other materials such as metals or even cement, developing more affordable and accessible 3D printers that can print alternative materials could lead more companies and consumers to invest in 3D printers. These printers would allow companies and consumers to produce a wider range of goods and things.

- Eco-friendly printing: 3D printing often produces a significant amount of wasted printing material. Finding ways to either convert wasted 3D printing filament back into usable filament or developing recyclable or biodegradable filament could have revolutionary implications for the future. If 3D printers are to one day replace traditional manufacturing processes, given their ability to print a near infinite range of things, the use of a completely recyclable or reusable 3D printing filament could potentially lead manufacturers to have fully closed-looped production systems in which all wasted material could be converted back into usable printing material. This would not only create more eco-friendly manufacturing processes, but it would likely help companies cut costs as well.

Innovations within these two areas of 3D printing could be the defining steps that bring the practice to the forefronts of manufacturing and production. The possibilities with 3D printing are limitless and there is no better time to start learning about 3D printing than now!

As I say to close out each of my videos,

This is Slomo, signing off. Take care.

About slomo's

slomo’s is a "Platform to Explore 3D Printing Together"! I created slomo’s to learn more about 3D printing and to teach others about 3D printing. I aspire to provide businesses and everyday consumers with the tools and opportunities needed to learn about 3D printing as it becomes a revolutionary practice within the global market. I also offer 3D printed products and 3D printing services such as commission printing and prototyping. slomo’s is currently on Instagram, YouTube, LinkedIn, and Etsy, but I plan to expand slomo’s onto other platforms in the future.

To learn more about slomo’s, check out my introduction video.

Make sure to follow and subscribe to slomo’s to begin your journey with 3D printing:

- Follow slomo’s on Instagram: @slomos3dprint

- Subscribe to slomo’s YouTube: slomos 3dprint

- Visit the slomo’s Etsy store: slomos3dprint

Do you have a question, comment or idea related to 3D printing or are in need of 3D printing services? Email me at slomos3dprint@gmail.com.